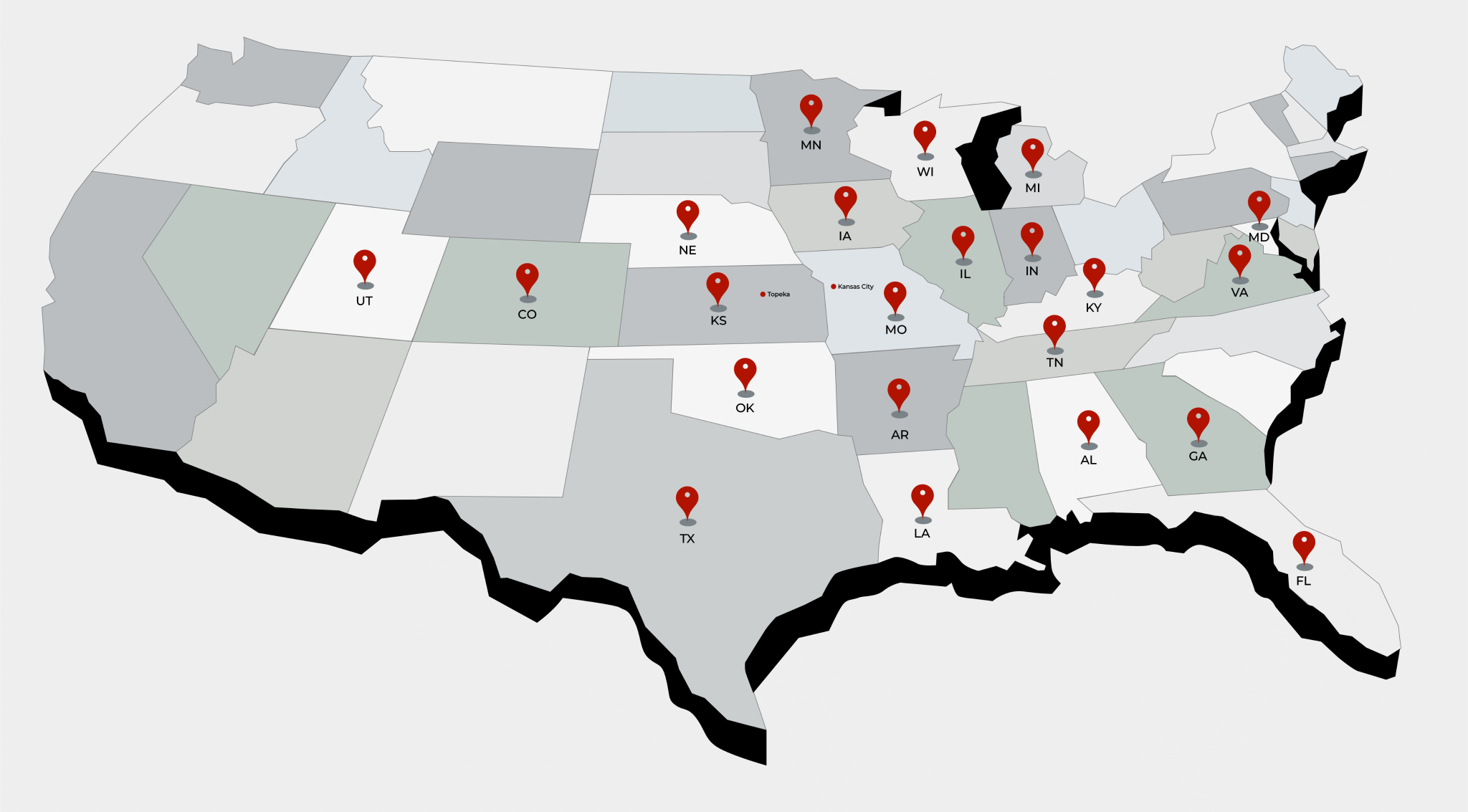

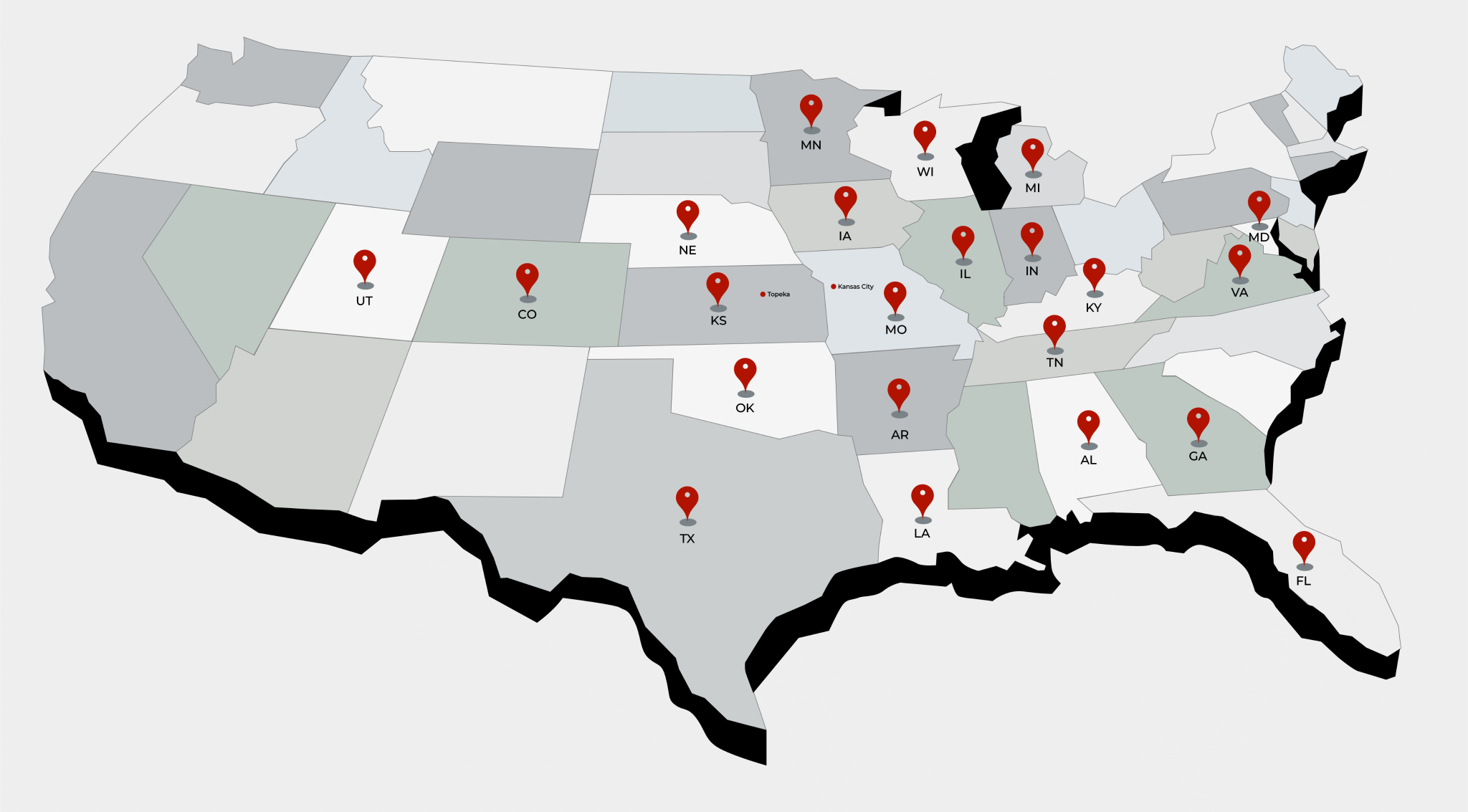

Areas Served

- Alabama

- Arkansas

- Colorado

- Florida

- Georgia

- Illinois

- Indiana

- Iowa

- Kansas City, MO

- Kentucky

- Louisiana

- Maryland

- Michigan

- Minnesota

- Missouri

- Nebraska

- Oklahoma

- Tennessee

- Texas

- Topeka, KS

- Utah

- Virginia

- Wisconsin

At ASG, we offer comprehensive industrial elevator service. Our technicians are skilled in all facets of elevator service and provide onsite technical analyses, emergency repairs, custom maintenance programs and remote elevator troubleshooting.

Whether you have a material hoist, transport platform, temporary or permanent elevator, ASG can assist you with service, installation and maintenance. We specialize in rack and pinion (Alimak, GEDA, Champion and other brands), traction or hydraulic elevators. No matter what system you have, we can perform the work!

Our expert elevator technicians not only perform professional installations of elevators, material hoists and transport platforms, but they also service and maintain each system after the install to prolong their lifespan. We also offer 24/7 emergency service on all elevators.

Service and maintenance are important parts of keeping your elevator running smoothly day after day. Our technicians are highly trained to make sure you are getting the most comprehensive service and maintenance available.

Call us today to schedule a consultation to discuss the best maintenance options for your system and budget.